Here are additional accessories and features that will allow for perfect customization of the devices to meet your needs (a more detailed description of the proposed solutions is provided below):

- heat recovery system;

- identification system;

- production data recording system with reporting;

- remote access to the device and receiving notifications on your phone;

- inspection window in the dryer door with interior lighting;

- audit trail;

- predictive maintenance package;

- specially made trays.

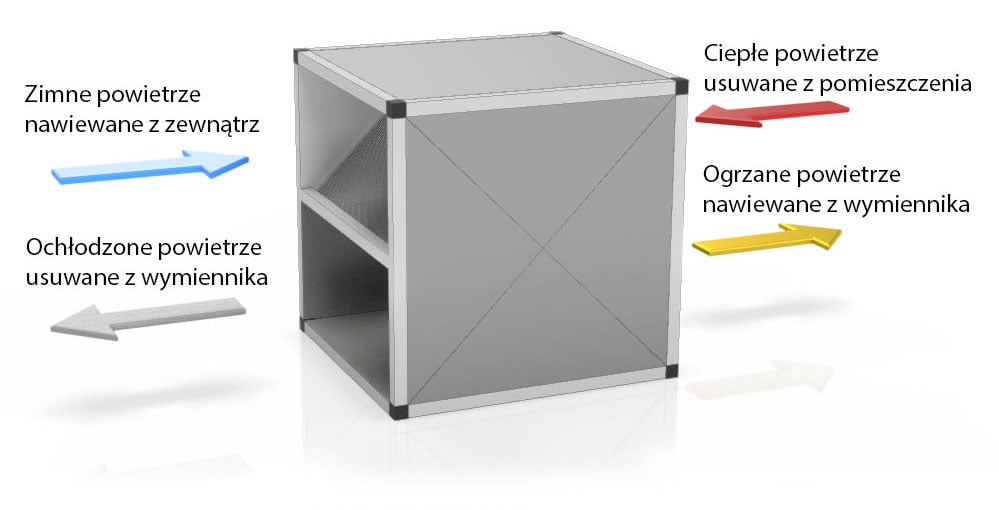

Recuperator It recovers heat from the exhaust air, thereby contributing to lower energy consumption required for the drying process.

Identification system It allows for tracking the progress and parameters of the production process, records data, and archives it for 5 years. We can provide the system together with a barcode reader, enabling automatic entry of serial numbers and production batch numbers.

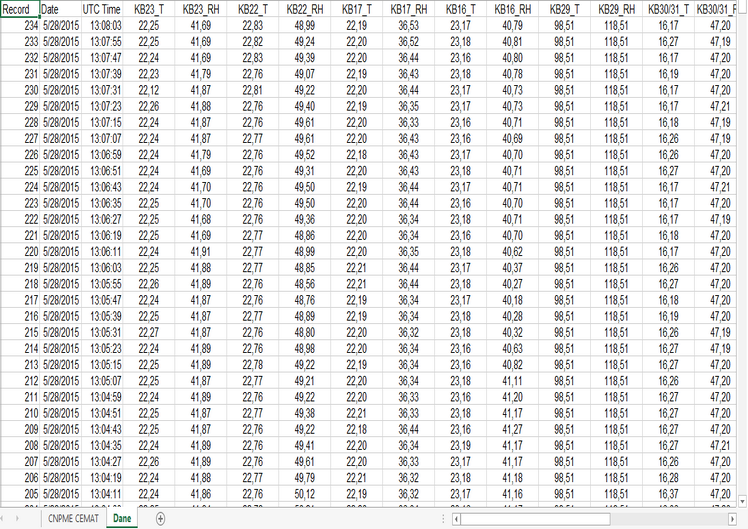

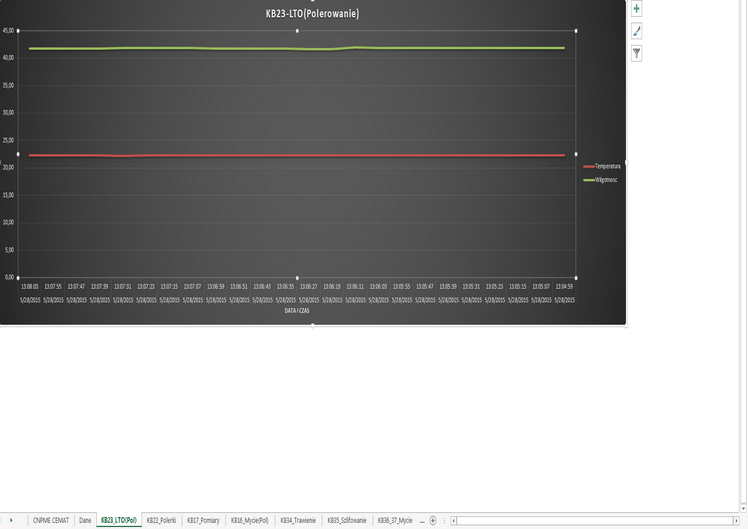

Production data logging system automatically archives data and, upon completion of the process, generates a report with predefined charts, which can be sent to a specified email address or saved in the cloud.

Inspection window in the dryer door and interior lighting allow the operator to have better control over the process and the condition of the product without opening the machine’s door. This helps maintain a constant temperature inside the dryer.

Audit trail allows for tracking changes in the process and recording its progress, which proves to be especially useful in the pharmaceutical industry.

predictive maintenance package monitors the operation of devices such as heaters or fans and informs the user of any potential issues, helping to avoid breakdowns. The package significantly increases machine availability and reduces downtime.

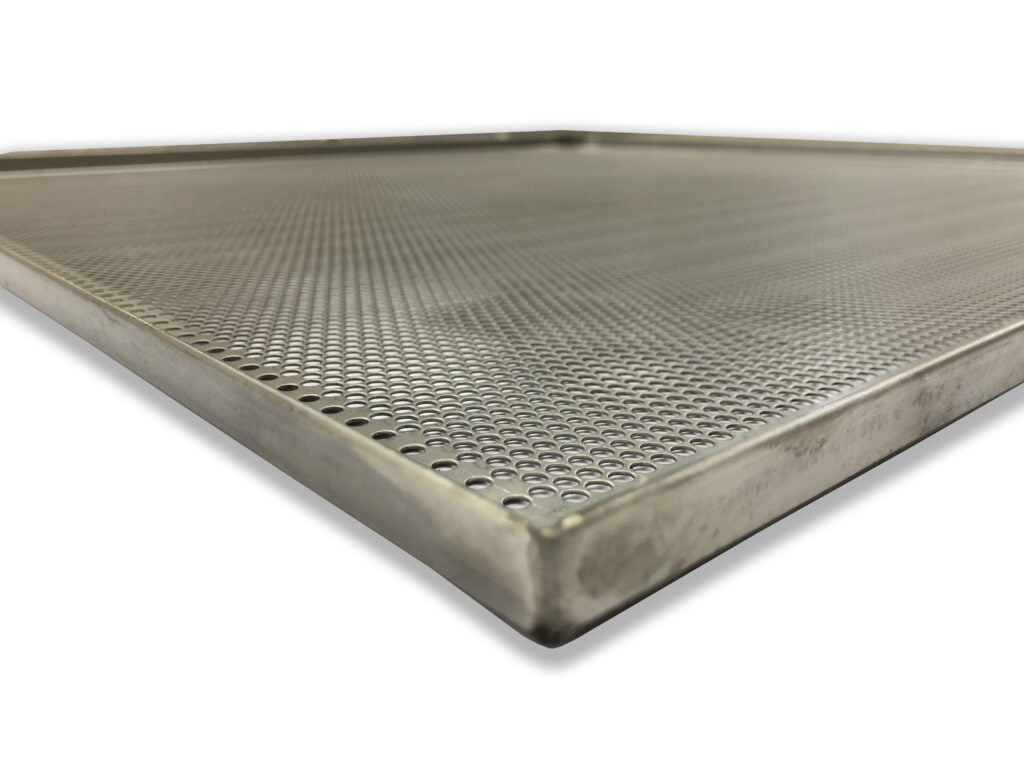

special design of drying trays reduces product adhesion. Trays can be coated with Teflon, nanocoatings, or silicone.